What is the compatibility and applicability of patch red glu

作者:点胶机厂家 日期:2019-06-24 14:45 浏览:

Patch red adhesive refers to a kind of adhesive commonly used in SMT patch and PCB board coating. Because of its rapid curing after heating, it is often used in patch coating. It is relatively easy to control and has good heat resistance, and has no solvent to meet the needs of modern environmental protection. High-speed dispensing machine has a strong promotion field and relatively comprehensive coverage in the industry. Under this kind of equipment, red adhesive can be controlled for coating film. The red glue dispensing machine is mainly used to stabilize the high-speed control effect and control the quality and efficiency of the coating.

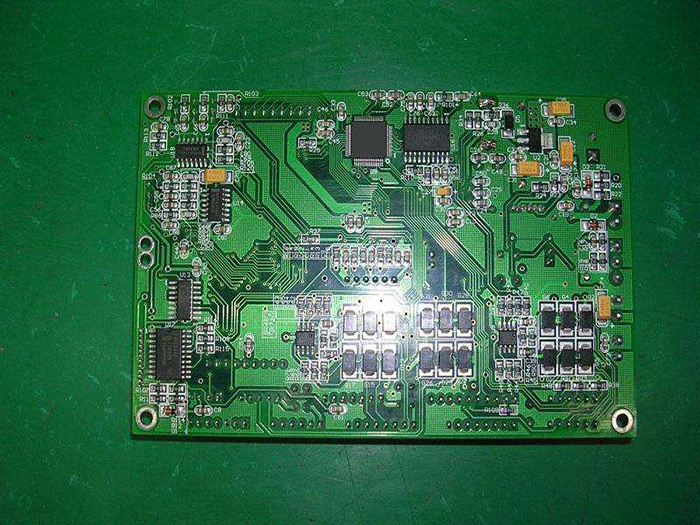

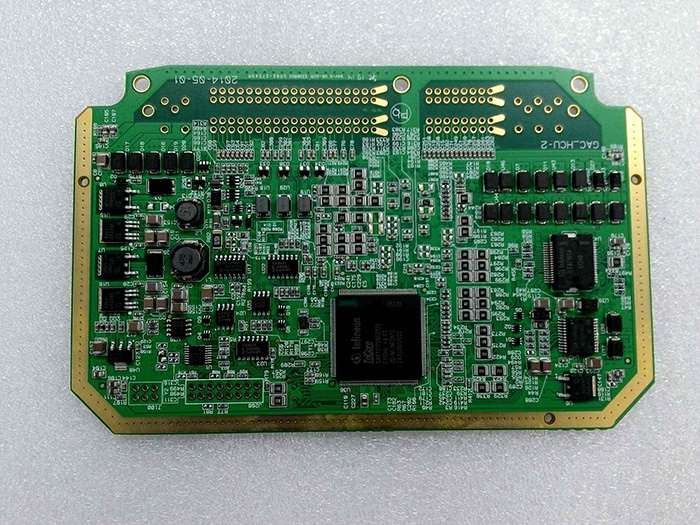

SMT special patch red glue

Application and Control of Red Rubber Patch

SMT patch links are mainly used to bond surface mounting elements to printed circuit boards before wave soldering. In this link, special red glue is used to achieve non-volatile bonding and high bonding strength. Red glue dispenser should be selected as an important equipment to control SMT patch quality and PCB coating effect in many high-speed dispensing machines, because it can adjust the built-in temperature to facilitate the control of red. The characteristics of glue coating and adhesive sheet can be used in this kind of application production. In practical application, the common problems of red glue coating must be paid attention to in order to apply the effect of the application of adhesive sheet.

SMT Patch Processing Technology

Common problems about red glue for patches

Because the quality of SMT patches and PCB sheets is reflected from the application of adhesives, the common problems of red glue coating are listed here.

What about storage?

Remove low-temperature red glue from refrigerator one day before application such as patch coating. Open the container cover after the patch red glue is at room temperature. This is to avoid the influence of water vapor condensation on high-speed patch coating. At the same time, it should be stored at - 2 - 9 C and used within the validity period.

Relevant adjustments?

Before using the patch red glue, mix the rubber evenly with stainless steel stirring rod. When the red glue is completely free of bubbles, place it in the pressure bucket matched by the red glue dispenser. Cover the container cover well after coating SMT patch and PCB board to avoid water and gas running in.

In order to prevent the hardening and deterioration of patch red glue, the patch red glue after stirring should be used up within 24 hours. The remaining SMT patch red glue should be stored alone and not mixed with the new patch glue.

Safety in use

Operators who adjust the red glue dispenser try to avoid the contact between the patch red glue and the skin. If they touch it carelessly, they should clean it with alcohol in time.

These are the manifestations of common problems of red glue coating, which need to be specifically adjusted to avoid affecting the normal operation of red glue dispensing machine.

Red glue on SMT patch links

The storage of red glue is related to the use of the whole coating. It is suggested that dispensing or coating operations should be stopped at constant temperature (- 3 ~23 ~C), because the viscosity of red glue changes with temperature, so as not to affect the quality of the coating.